HPL vs. Melamine: Choosing the Right Surface for Your Cabinets

For decades, cabinet finishes have been chosen with a fairly straightforward logic: keep it affordable, keep it durable, and make it look good enough to last through the trends. But as kitchens, wardrobes, and home offices evolve into design statements in their own right, the choice of surface materials has become less about “good enough” and more about getting it right. The modern cabinet finish isn’t just a protective skin—it’s a daily touchpoint, a marker of style, and a key player in how well the furniture performs over time.

Among the most popular contenders are melamine and high-pressure laminate (HPL). Both promise sleek looks and practical performance, yet they serve different purposes depending on budget, lifestyle, and design goals. For homeowners and designers, the question isn’t just which one looks better, but which one will stand up to real life—from daily cooking messes to kids’ fingerprints to long-term wear and tear. Understanding how each material is made, what it excels at, and where it falls short is the first step to making a choice that balances function with aesthetics.

HPL Cabinets: Durable, Versatile, and High-Performing

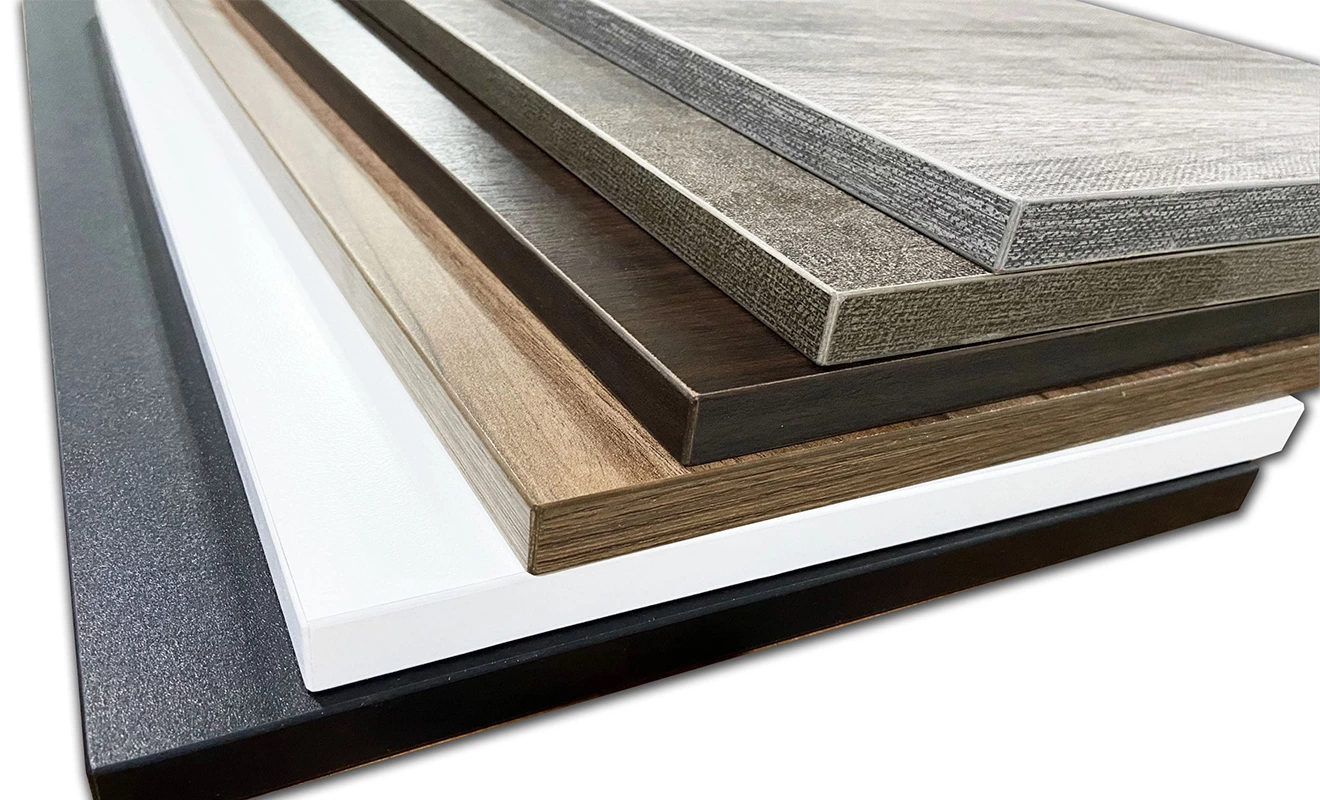

High-Pressure Laminate (HPL) is created by stacking multiple layers of kraft paper, soaked in resin, and pressing them together under extreme heat and pressure. The result is a hard, compact sheet that is then bonded to a core material like MDF or particle board. This construction gives HPL outstanding strength, resilience, and versatility.

Advantages of HPL

Exceptional Durability: Built under high pressure with multiple resin-soaked kraft papers and a decorative surface, HPL is tough against scratches, abrasion, and impact.

Moisture and Heat Resistance: Better at resisting humidity and moderate heat compared to melamine, making it a smart choice for kitchens and bathrooms.

Design Versatility: Available in a wide spectrum of colors, woodgrains, and even textured finishes that mimic natural stone or concrete.

Longer Lifespan: Holds up well over years of daily use, especially in high-traffic areas.

Premium Look and Feel: Its finish often feels more substantial and upscale, appealing to homeowners seeking a high-end aesthetic without going full stone or veneer.

Limitations of HPL

Higher Cost: More expensive than melamine due to its layered manufacturing process.

Edge Sealing Required: Exposed edges need careful finishing to prevent moisture ingress.

Heavier Panels: Adds weight to cabinet doors and drawers, which may require sturdier hardware.

Melamine Cabinets: Lightweight, Affordable, and Everyday-Friendly

Melamine is made by directly fusing a decorative paper onto particle board or MDF using heat, pressure, and resin. It’s a thinner, lighter finish compared to HPL, and is one of the most widely used cabinet materials in cost-effective projects.

Advantages of Melamine

Budget-Friendly: One of the most economical cabinet finishes available, making it perfect for large projects or budget-conscious homeowners.

Smooth, Consistent Surface: The decorative paper finish delivers a uniform look with crisp edges.

Variety of Colors and Patterns: Comes in numerous solid colors and wood-look designs, offering flexibility for simple, modern kitchens.

Easy to Clean: Resists stains and requires minimal maintenance—just wipe down with a damp cloth.

Lightweight: Easier on hinges and hardware compared to heavier HPL.

Limitations of Melamine

Lower Durability: More prone to chipping, scratching, and peeling over time, especially along edges.

Moisture Sensitivity: Can swell or blister if exposed to prolonged humidity without edge sealing.

Less Heat Resistant: Susceptible to heat damage, so placement near stoves or ovens requires caution.

Shorter Lifespan: While affordable upfront, may need replacing sooner than HPL if used in high-wear areas.

How to Tell HPL from Melamine

Surface Feel: HPL tends to feel thicker, more textured, and robust, while melamine feels smoother and thinner.

Edge Detail: HPL usually requires edge banding; melamine often comes pre-finished with sealed edges.

Weight: HPL panels are noticeably heavier than melamine.

Price Tag: If the finish feels high-end and the price is higher, chances are it’s HPL.

Feature Comparison Table

| Feature | HPL | Melamine |

| Cost | higher | lower |

| Durability | very high (scratch, impact, heat resistant) | moderate (can chip/scratch) |

| Moisture Resistance | strong (with proper sealing) | low (edges vulnerable) |

| Weight | heavier | lightweight |

| Design Options | extensive, realistic textures | wide, but less detailed |

| Ease of Maintenance | easy to clean, hygienic | easy, but edges delicate |

| Lifespan | longer | shorter |

Choosing the Right Surface for Your Cabinets

When deciding between HPL and melamine, think about your home’s lifestyle and the role of each space:

Kitchens & Bathrooms: HPL shines in moisture-heavy, high-traffic environments where durability is key.

Wardrobes & Storage Units: Melamine works well for closets, bedroom storage, or office cabinetry where budget and lightweight doors matter more than extreme durability.

Living Areas & Accent Pieces: A mix of both can deliver the best of both worlds—HPL for frequently used cabinets, melamine for less demanding storage.

Conclusion

At the end of the day, both HPL and melamine have their rightful place in modern cabinetry. HPL offers a tough, stylish, and long-lasting finish that excels in kitchens, bathrooms, and other heavy-use areas. Melamine, on the other hand, is a cost-effective, lightweight solution perfect for wardrobes, bookcases, and secondary storage.

For whole-home custom cabinetry, a smart approach is to combine the two strategically — use HPL where performance and resilience are non-negotiable, and melamine where budget and practicality lead the way. This layered strategy not only keeps costs balanced but also delivers a cohesive, high-end look that aligns with the needs of everyday living.